The recent pandemic-induced lockdowns and global recession led to several structural disruptions across the procurement and supply chain sectors. Technology proved essential for successfully navigating this change, implementing social distancing, and mitigating risks in warehousing and distribution. As businesses shift their focus to reducing manual dependency and automating the front-end and back-end processes, Robotic Process Automation (RPA) has become critical for enabling Supply Chain Management (SCM) 4.0.

Supply chains have long been plagued by error-prone and time-consuming approaches, expensive logistical operations, heavy dependency on legacy systems, manual processes that impede scale, and a lack of data-led insights. Workers waste hours in excess motion that amount to almost $4.3 billion worth of labor. The mounting pressure from customers who expect faster and more personalized services has further estranged SCM to recalibrate order fulfillment while adhering to regional regulations and obligations. In response, retailers have already been making a move towards an 'always on' agile supply chain with automated monitoring of logistical elements, last-mile deliveries, and warehouse management.

Estimates suggest that manufacturers will automate 50% of processes by 2022, and collaborative robots will supplement 30% of operational warehouse workers by 2023. For an industry primarily driven by accuracy, speed, and precision, RPA serves as a boon to reduce the scope of errors and allow leaders to focus on more strategic tasks.

Is automation a reality for SCM?

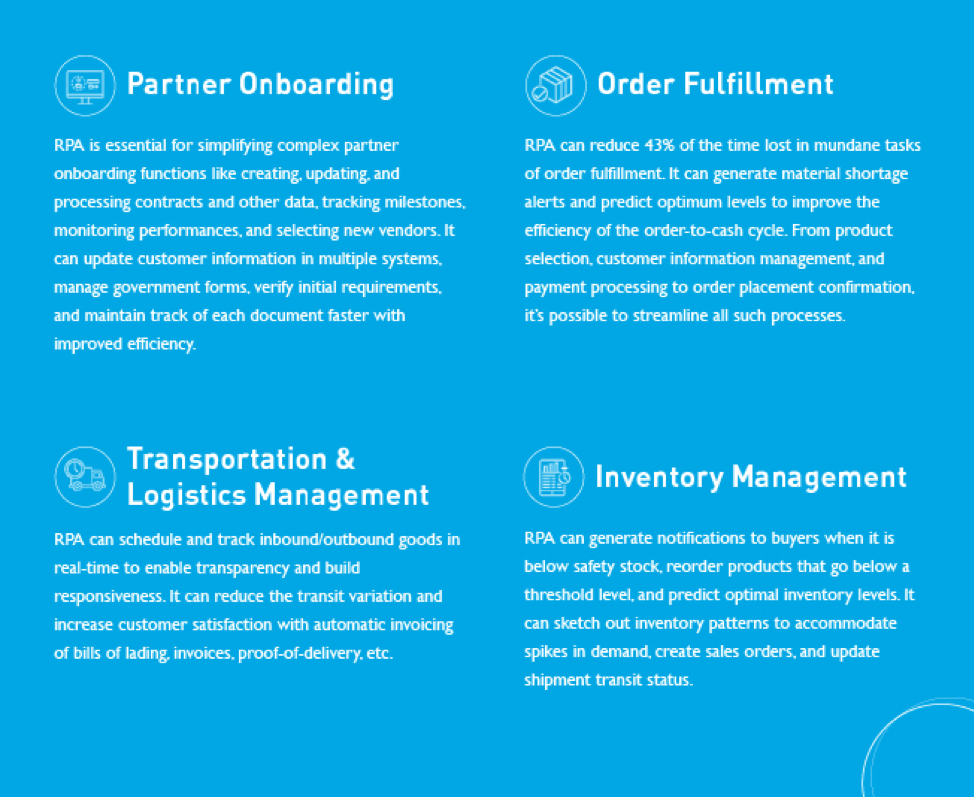

Building an RPA solution is just one part of enabling next-gen supply chain management. The key is to understand the variety of use cases, deploy a modular version, and extend the solution's scope for specific needs. This way, RPA can become the autopilot of SCM capable of functions like order fulfillment, product designing, inventory monitoring, and synchronization with sourcing and production.

- Eliminate manual inputs from administrative tasks - RPA helps match inventory stock levels, raise purchase orders, and streamline the recruitment and training processes.

- Respond to proposals, quotes, and questions - RPA parses, understands, and responds to communications with trigger emails and status alerts for faster turnaround and accurate responses.

- Identify supply chain efficiencies - RPA provides actionable insights into highly repetitive processes for streamlining supply chain processes, reducing delays, and paving the way for continuous growth.

- Seamless integration with other systems - RPA works for multiple software, systems, and tools used by stakeholders throughout the supply chain to reduce duplication.

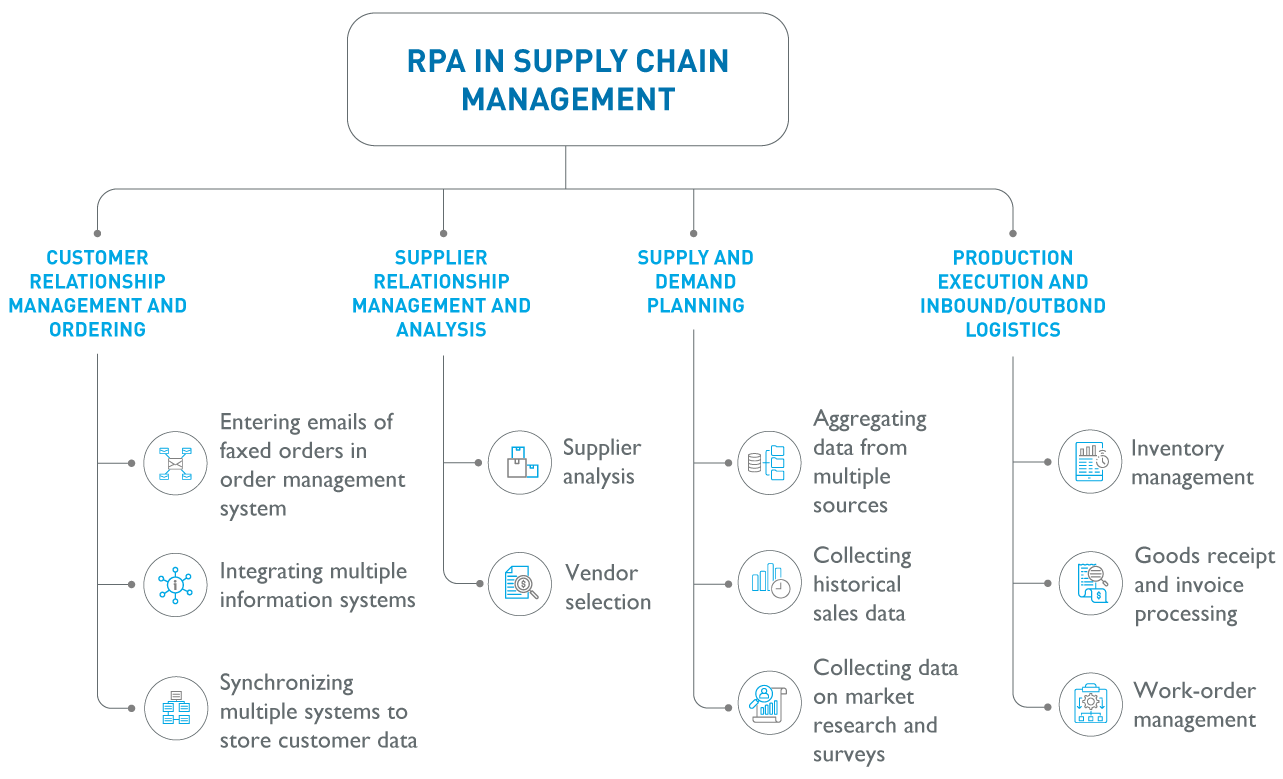

However, businesses mustn't just dive into RPA for a rapid, low-cost way to automate rule-based processes. Instead, they must understand the mapping of use cases into SCM deliverables to successfully reap the benefits. Here are a few domains in which RPA can be useful.![]()

With the advancements in automation technology and the incorporation of capabilities like cognitive computer vision and intelligent OCR (Optical Character Recognition), the advanced RPA versions can expand their scope beyond the defined rules of processing inputs. They can create supply chain networks that are more open, flexible, connected, and decentralized. SCM leaders don’t even need to be involved intrinsically in standard processes (unless face-to-face negotiation is required.) A well-executed RPA solution can streamline operations with speed and scalability.

Tap into a new realm of possibilities

With RPA, supply chains can enhance cycle time, improve agility, increase asset efficiency, and satisfy multiple stakeholders with better collaboration opportunities. RPA can assist third-party logistics providers (3PLs) in developing multi-user warehouses, automating lean processes, and creating “plug-and-play" implementation methodologies. It draws considerable difference from traditional workflows.![]()

With the right strategy, tools, and know-how, RPA can accelerate SCM performance and enable decision-makers to:

- Quickly adapt to demand and scale up operations.

- Reduce administrative overhead and staffing costs.

- Free employees from repetitive tasks.

- Virtually eliminate human error and duplication for less rework, higher quality outputs, and more streamlined processes.

- Identify inventory needs and deliver stocks timely.

- Focus on value-added tasks to generate more revenue and drive improvements.

- Enhance access to dangerous locations and optimize selecting, sorting, and storing times.

- Accelerate time to value.

- Increase throughput by completing tasks in minutes.

Reap endless benefits

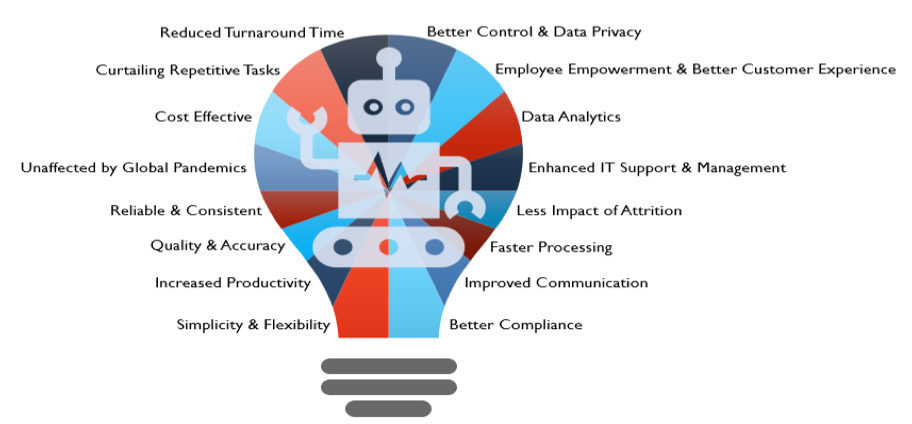

In addition to the obvious benefits, it's also important to acknowledge the foresight needed to leverage RPA successfully at scale. Companies require RPA governance teams and partners to steer customized projects through process selections, technology support, and reskilling programs.

In addition to the obvious benefits, it's also important to acknowledge the foresight needed to leverage RPA successfully at scale. Companies require RPA governance teams and partners to steer customized projects through process selections, technology support, and reskilling programs.![]()

Enable transformation leveraging HARMAN solutions

HARMAN understands the importance of fostering an automation-first mindset for continued value generation and future gains. We build a holistic vision inside-out with a feasible strategy instead of a piecemeal approach to automation.

Apart from powerful software and platform development capabilities, we also have horizontals dedicated to Design, Cloud, Analytics, and Staffing to promote continuous innovation, quicker turn-around times, and attractive cost-efficiency. Our comprehensive suite of software products, solutions, and services facilitates intelligent robotic automation and next-gen solutions. Our consultants can help organizations to assess SCM areas where repetitive tasks can be automated using RPA. This can free employee bandwidth, enabling them to focus on more critical activities, new challenges, and value-added activities.

CONTACT US to revitalize your supply chains at a global scale by creating intelligent process automation and cognitive learning capabilities with HARMAN solutions.